Overview

Purpose: Class project for Physical Prototyping

Instructor: Noah Posner

Timeline: October 2019 - November 2019

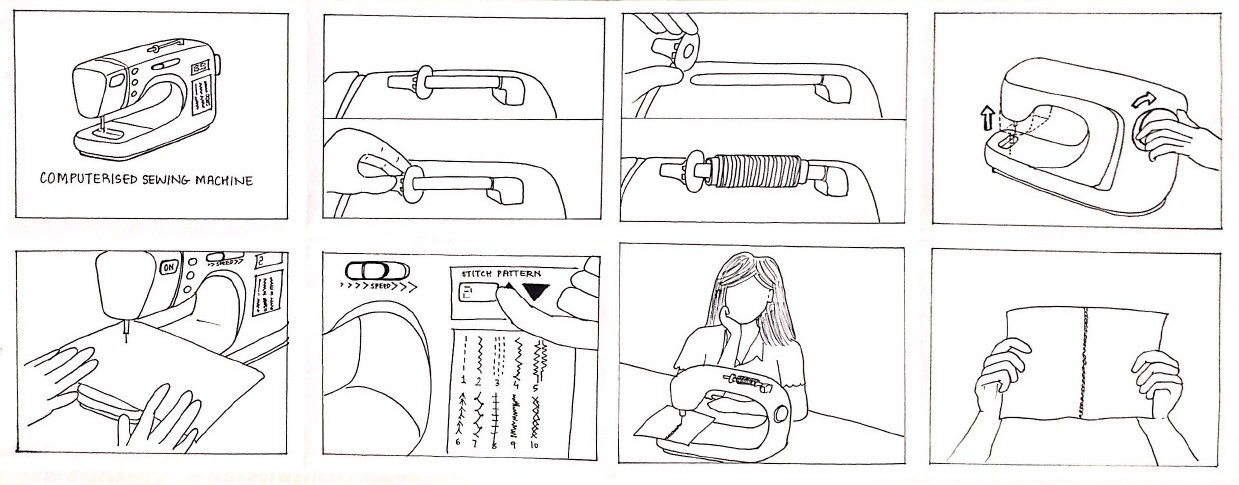

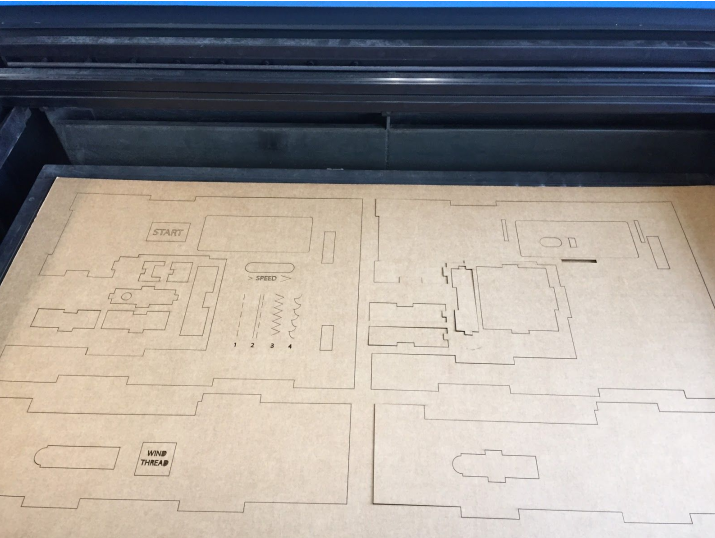

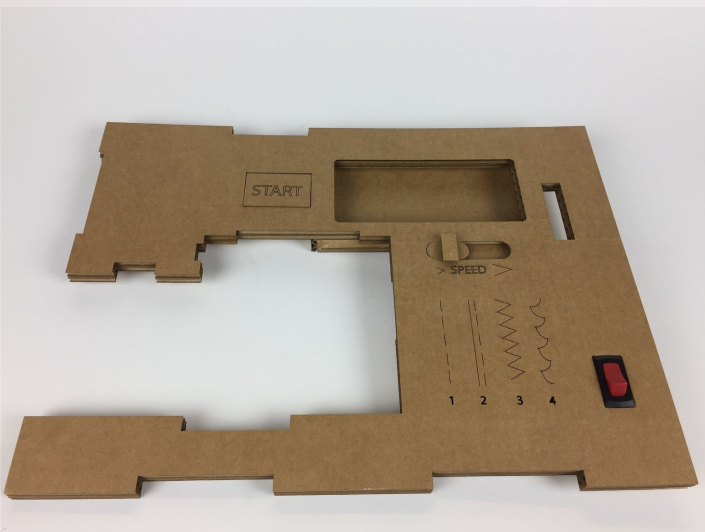

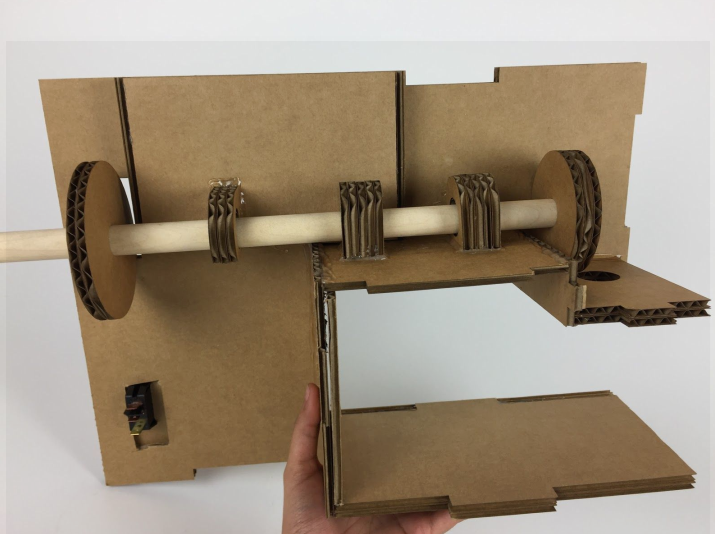

Tools: Storyboarding, CAD modelling, Solidworks, Adobe Illustrator, Laser Cutting, Informal Usability Testing

Team: Individual project

Contributions: Designed interaction, created the box model in Solidworks, fabricated the prototype from laser cut parts, tested the interactions with users.